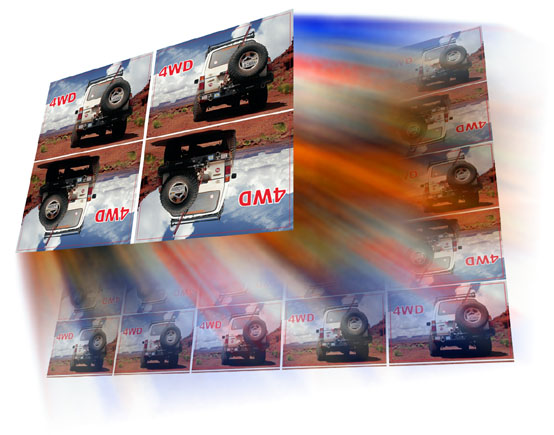

MaxStep provides a mixture of tools and options to create step-and-repeat layouts for a wide variety of printing processes.

With MaxStep, users have the ability to interactively create step-and-repeat layouts, or use pre-defined die cut guides to automatically generate layouts according to the requirements of the printer or converter.

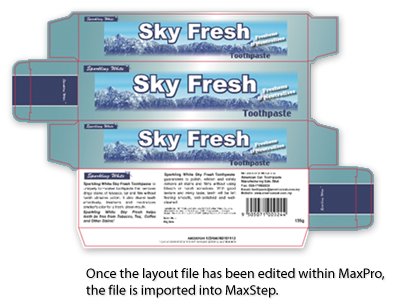

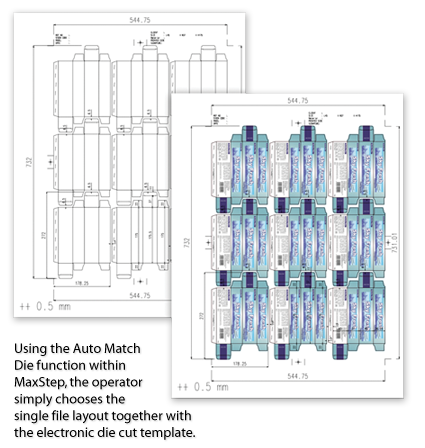

In automatic mode, the Auto Match Die facility within

MaxStep allows users to import CAD generated Die

cutter guides which define the placement and amount

of items to appear on the layout.

MaxStep then scans the incoming cutter guide and automatically matches the 1-up original to produce a final layout as defined by the master Die cut guide.

This unique tool presents operators with a fast, accurate match between the 1-up original and the repeated image without the need for time consuming placement or measuring.

The Interactive Step and Repeat facility enables users to choose a layout and plate size, and define the step gap, number of repeats, order, border and any stagger as required.

Files are then automatically stepped and repeated on the sheet as defined.

Pre-defined sheet sizes can also be filled efficiently with an image, simply by choosing a fit style offering seamless and continuous repeats.

MaxStep offers a wide range of registration, trim and color mark options. Color control bars for process and spot colors can be applied dependent on the requirement on press. Additional to the standard library containing barrel, pressure, trim and register marks, users have the facility to import custom marks created in design packages such as Adobe Illustrator.

A numbering feature enables dynamic placement of unique numbers to items stepped and repeated. This serves as a convenient quality control function and enables easy identification of individual items on a sheet.