Star Plate uses the actual dots of the original RIPped 1-bit data,preserving dot patterns, screening and dot gain calibration. The 1-bit data can be produced by Harlequin RIP or other RIP.

Star Plate provide powerful controls of imaging on inkjet printer to produce high quality dot formation with the foundation of it’s

analytical engine. The software can produce very fine solid hard dot and great 150 lines per inch results with halftone screening.

Allows user to choose substrate in any sizes between the range of 406

mm to 1,118mm. The size is depend on Epson printer model choosen.

Imaging to inkjet coated film/plate does not need to use any processing

chemical. It eliminate the hassle of chemical consumption, supplies and maintenance cost. Hence it is an environment friendly solution.

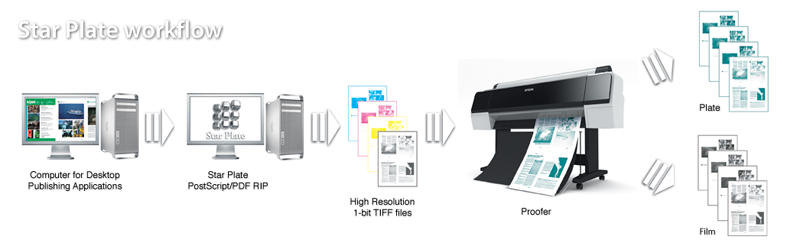

To setup a Star Plate inkjet CTP/CTF is much easier compare to

ordinary CTP/CTF system workflow and it does not require large

installation space.

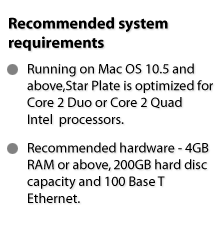

Star Plate software runs on Apple Mac computer, the most popular platform in graphic art industry. Easy to use, powerful, compatible, stable, secure, easy for installation and configuration. With simple

operation features, operators able to manage without pressure.

Allows user setup individual calibration curve to suit different dot

gain required from the press. Adjustment can be done easily in the RIP for fine tuning calibration curve.

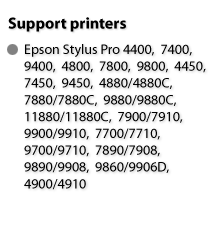

Utilize with the VSDT-capable Epson Stylus Pro printers to increasing output quality. No compulsory change made to the inkjet printer internal mechanism for printing with film or plate.

Star Plate

Why Star Plate?